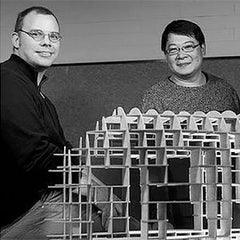

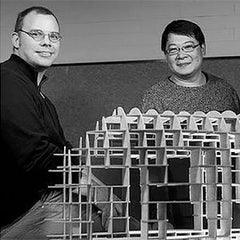

Click for more ideas from Paul Loh + David Leggett (designer)

Click for more ideas from Paul Loh + David Leggett (designer)

Power to Make is uniquely set up as a micro-manufacturing facility located in Preston, Melbourne. All products are designed and made in house by founders Paul Loh and David Leggett, the duo (aka LLDS) both trained and practiced as architects in the UK and have extensive research knowledge in digital fabrication and craft.

As a micro-manufacturing facility Power to make are not restricted to mass producing a single type of product to minimised running cost. Being micro, they can be more responsive to client’s requests and demands. They explore making directly from digital model to physical object; merging craft with digital processes. This way of making allows the company to have a continuous feedback between how the furniture performs and its aesthetic, allowing them to craft and refine the digital information they use to make our product.

Continue Reading